Training and Education:

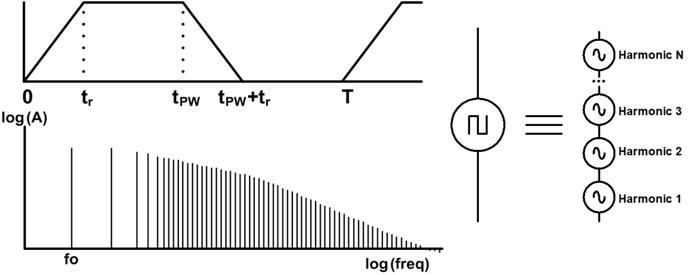

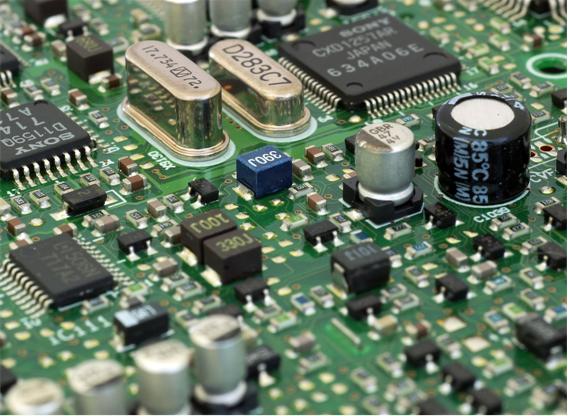

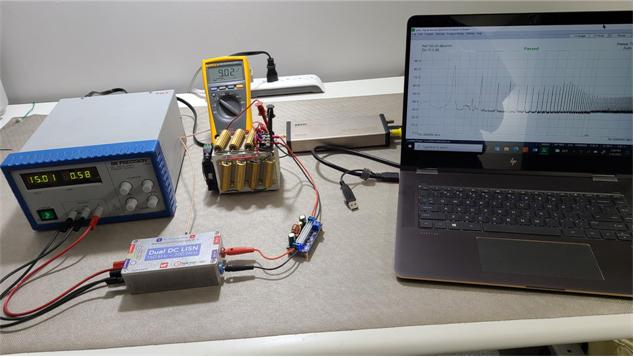

Dr. Schutten has taught well over 3000 engineers with technical training. He has taught more than a dozen 1/2 day IEEE seminars, multiple universities, government laboratories, and Fortune 500 companies. The seminars include fundamental EMC understanding, the equivalent coupling methods, layout methods, and testing techniques. There are seminars that specialize in EMC for power electronic converters, and provide methods to characterize and improve EMC performance, layout and decoupling for low-noise operation, and discusses the EMI effects of using wide bandgap semiconductors such as silicon carbide Mosfets.

Here are links to descriptions of a couple of STC seminars:

EMI: Theory, Coupling Mechanisms, Equivalent Circuits, and Solutions

EMI Causes, Measurement, and Reduction Techniques for Switch-Mode Power Converters